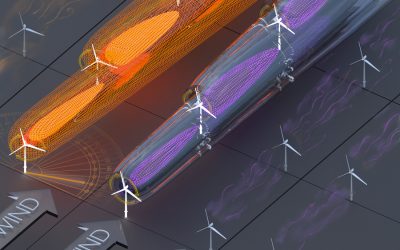

The two side-compartments for the Vestas V236-15.0 MW™ prototype wind turbine nacelle have arrived in Denmark.

The side-compartments were then transported to Vestas’ factory in Esbjerg, where the full power converter system will be installed.

Image Source: Vestas

According to Vestas, the modular nacelle components take full advantage of industrial standards, as the side-compartments are dimensionally designed to correspond to general industry standards rather than challenging them.

The modularised nacelle is divided into a main nacelle house, and one or more side-compartments depending on configuration, that are dimensionally designed to correspond to logistics standards such as shipping containers, for road, rail, and ocean transportation.

This means that the modularised nacelle units can be transported while adhering to tunnels, bridge heights, rail systems, etc. with less need for specialised handling.

Side-compartments can, in general, house many different types of relevant technologies or applications, Vestas said.

Utilising a simple click-on system, the modular concept is said to facilitate smart servicing solutions and opens up upgrade and innovation possibilities over the lifetime of the operating asset.

Vestas plans to expand the modularisation approach to encompass the whole turbine.

The Danish turbine manufacturer has already applied the modularised nacelle concept to its latest onshore turbine – the EnVentus V162-6.8 MW™.

The company plans to install the V236-15 MW prototype offshore wind turbine at the Østerild National test centre for large wind turbines in Western Jutland, Denmark later this year.

The wind turbine will feature 115.5-metre blades, the world’s longest.

Stretching 280 metres into the air with a production output of 80 GWh/year, the prototype will be the tallest and most powerful wind turbine in the world once installed, Vestas said.

The globally applicable offshore turbine is said to offer 65 per cent higher annual energy production than the V174-9.5 MW, and for a 900 MW wind farm it increases production by five percent with 34 fewer turbines. It is said to offer excellent partial-load production, resulting in a more stable energy production, and a capacity factor over 60 per cent depending on site-specific conditions.

Launched in February 2021, Vestas secured its first pre-selected tenderer status for the V236-15.0 MW turbine in July 2021 for the 900 MW He Dreiht project in Germany.

The model has since been chosen by Equinor and bp for their 2.1 GW Empire Wind 1 and Empire Wind 2 wind farms offshore New York.

- KHANG DUC IS NOMINATED ON TOP 3 FOR “EPC COMPANY OF THE YEAR”, ORGANIZED BY COMMITTEE OF WIND FUTURE AWARDS 2021

- EPC & BOP Wind farm contractor in Viet Nam

- Khang Duc’s Construction sequences of Offshore Windfarm

- Khang Duc’ Energy Projects

Source: offshoreWIND.biz